- We

- Renewable Energy

- Calibration Service

-

Testing & Inspection

- Annual Inspection

- Energy Audit

- Transformer Testing

- Condition Monitoring

- HiPot Testing

- Circuit Breaker Test

- Insulation Testing

- CT/PT Analysis

- Earthing Inspection

- Environmental Inspection

- Flue Gas Analysis

- LV, MV, HV Switchgear Testing

- DEA (Detail Engineering Assessment)

- Correlation of Compressive Strength of Concrete

- Mapping Homogeneity of Concrete Test

- Defects of Concrete Subsurface Test

- Concrete Pile Length Assessment Test

- Mapping of Concrete Plate Thickness

- Pile’s Internal Defects, Voids Assessment Test

- Pile Load Test

- Concrete Column Test

- Pipes Hardness Test

- Heat-Treated Surfaces Inspection

- Rebar location Assessment

- Crack Assessment

- Metal Detection & Analysis

- Drilling Spot Findings

- Concrete Compressive Strength

- Concrete Uniformity Mapping

- Shallow Utility Location Assessment

- Pipeline Inspection & Assessment

- Excavation Safety Assessment

- Utility Locating & Mapping

- Penetration Test

- Welding Inspection of Pressure Vessel

- Defects Analysis in Welding

- Adhesive Strength Test

- Pull Off Testing

- Skid Resistance Test of Construction Floors

- Concrete Resistance Measurement

- Building Information Modeling (BIM)

- Augmented Reality (AR) Assessment

- Virtual Reality (VR) Assessment

- Digital Twin Creation

- Partial Discharge Analysis

- Power Quality Analysis

- Photovoltaic Test

- Relay Testing

- SF6 Leak Detection

- Surge Protection Device

- Shaft Alignment Diagnosing

- Substation Testing & Commissioning

- Thermography Analysis

- Ultrasonic Flow Analysis

- Ultrasound Leak Detection

- Conveyer Belt Inspection

- Videoscope Inspection

- Switchgear Testing Service

- Solar Irradiance Measurement Service

- Contact Resistance Test Service

- Rent Products

Thermocouple Sensor

- Home

- Thermocouple Sensor

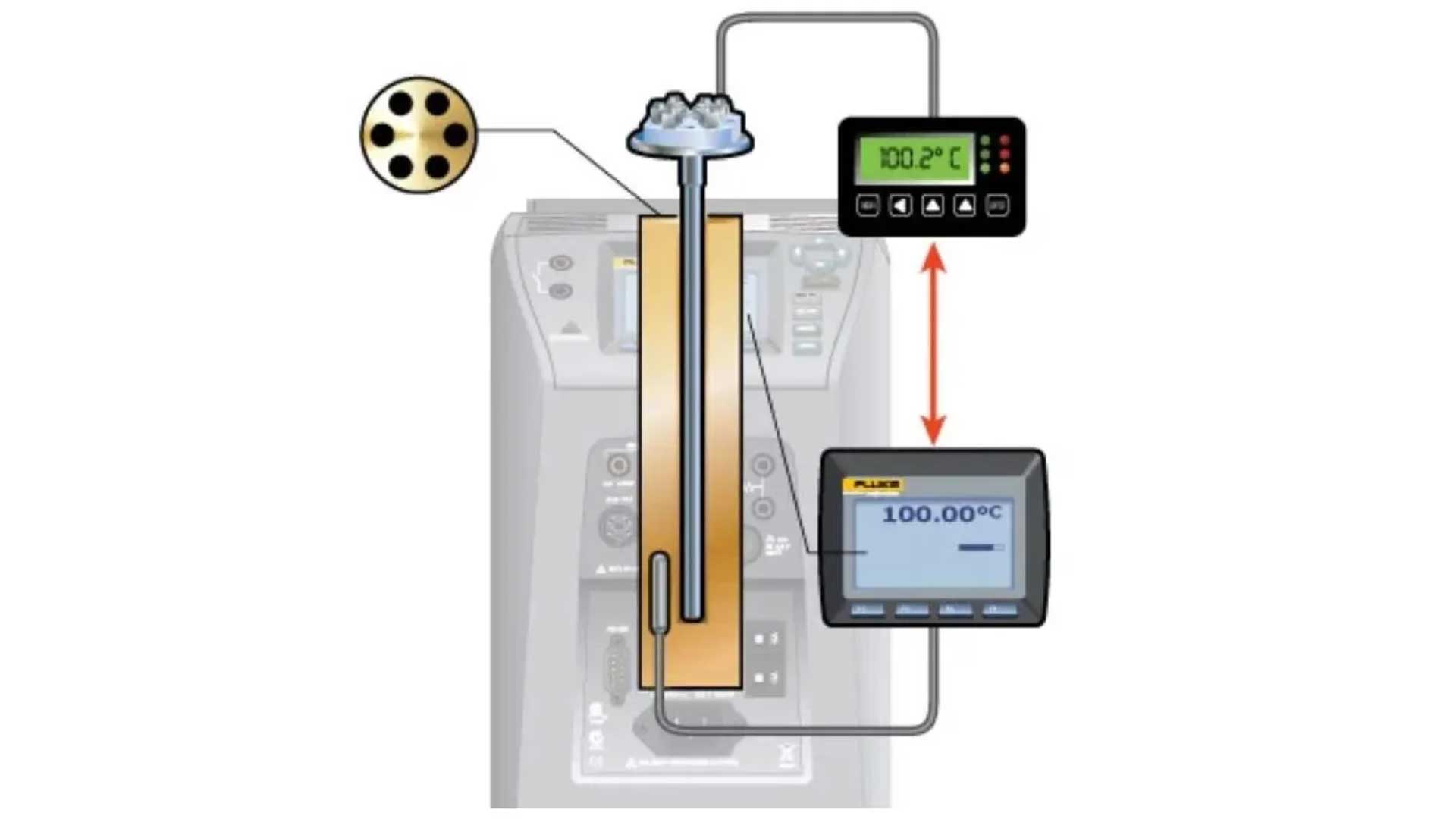

Thermocouple Sensor Calibration in Bangladesh

Thermocouple sensors are widely used in industries for precise temperature measurement, from power plants to manufacturing facilities. Over time, these sensors can drift due to environmental conditions, wear and tear, or exposure to extreme temperatures. This is where thermocouple sensor calibration becomes essential to ensure accurate readings and maintain operational efficiency.

Why Thermocouple Sensor Calibration is Important

Accurate temperature measurement is crucial for maintaining product quality, safety, and energy efficiency. An uncalibrated thermocouple can lead to errors that impact production, result in energy wastage, or even compromise safety in sensitive industrial processes. Regular calibration ensures that the sensors provide reliable and precise data, reducing risks and enhancing process control.

Calibration Process

Thermocouple calibration involves comparing the readings of the sensor with a known reference standard at specific temperatures. The process identifies any deviations and allows technicians to adjust the sensor or record the correction factors. Calibration can be performed on-site for convenience or in a specialized laboratory for higher accuracy.

Key steps in the calibration process include:

-

Preparation: Cleaning the sensor and ensuring proper installation.

-

Temperature Measurement: Using a standard reference, the sensor is tested across its temperature range.

-

Comparison and Adjustment: Deviations are noted and corrected if necessary.

-

Documentation: Calibration certificates are issued to ensure traceability and compliance with industrial standards.

Pico Labs Ltd. – Your Trusted Calibration Partner in Bangladesh

At Pico Labs Ltd., we specialize in high-precision thermocouple sensor calibration services across Bangladesh. Our state-of-the-art calibration laboratory and experienced technicians ensure that your sensors meet international standards, guaranteeing accuracy and reliability. With a commitment to quality, we help industries maintain optimal performance while reducing downtime and operational risks.

Benefits of Professional Thermocouple Calibration

-

Improved Accuracy: Ensures temperature readings are precise and reliable.

-

Enhanced Safety: Reduces the risk of temperature-related hazards in industrial processes.

-

Regulatory Compliance: Meets ISO and other industry-standard calibration requirements.

-

Cost Efficiency: Prevents energy waste and reduces the likelihood of costly production errors.

Why Choose Pico Labs Ltd.

With years of expertise in electrical and sensor calibration, Pico Labs Ltd. has earned a reputation for excellence in the industry. Our team not only calibrates thermocouples but also provides expert advice on sensor maintenance and best practices. Choosing Pico Labs Ltd. means choosing accuracy, reliability, and industry-leading service in Bangladesh.

Investing in regular thermocouple sensor calibration is a smart decision for any industry relying on precise temperature measurements. Ensure your operations run smoothly with the trusted services of Pico Labs Ltd., the leading calibration provider in Bangladesh.