- We

- Renewable Energy

- Calibration Service

-

Testing & Inspection

- Annual Inspection

- Energy Audit

- Transformer Testing

- Condition Monitoring

- HiPot Testing

- Circuit Breaker Test

- Insulation Testing

- CT/PT Analysis

- Earthing Inspection

- Environmental Inspection

- Flue Gas Analysis

- LV, MV, HV Switchgear Testing

- DEA (Detail Engineering Assessment)

- Correlation of Compressive Strength of Concrete

- Mapping Homogeneity of Concrete Test

- Defects of Concrete Subsurface Test

- Concrete Pile Length Assessment Test

- Mapping of Concrete Plate Thickness

- Pile’s Internal Defects, Voids Assessment Test

- Pile Load Test

- Concrete Column Test

- Pipes Hardness Test

- Heat-Treated Surfaces Inspection

- Rebar location Assessment

- Crack Assessment

- Metal Detection & Analysis

- Drilling Spot Findings

- Concrete Compressive Strength

- Concrete Uniformity Mapping

- Shallow Utility Location Assessment

- Pipeline Inspection & Assessment

- Excavation Safety Assessment

- Utility Locating & Mapping

- Penetration Test

- Welding Inspection of Pressure Vessel

- Defects Analysis in Welding

- Adhesive Strength Test

- Pull Off Testing

- Skid Resistance Test of Construction Floors

- Concrete Resistance Measurement

- Building Information Modeling (BIM)

- Augmented Reality (AR) Assessment

- Virtual Reality (VR) Assessment

- Digital Twin Creation

- Partial Discharge Analysis

- Power Quality Analysis

- Photovoltaic Test

- Relay Testing

- SF6 Leak Detection

- Surge Protection Device

- Shaft Alignment Diagnosing

- Substation Testing & Commissioning

- Thermography Analysis

- Ultrasonic Flow Analysis

- Ultrasound Leak Detection

- Conveyer Belt Inspection

- Videoscope Inspection

- Rent Products

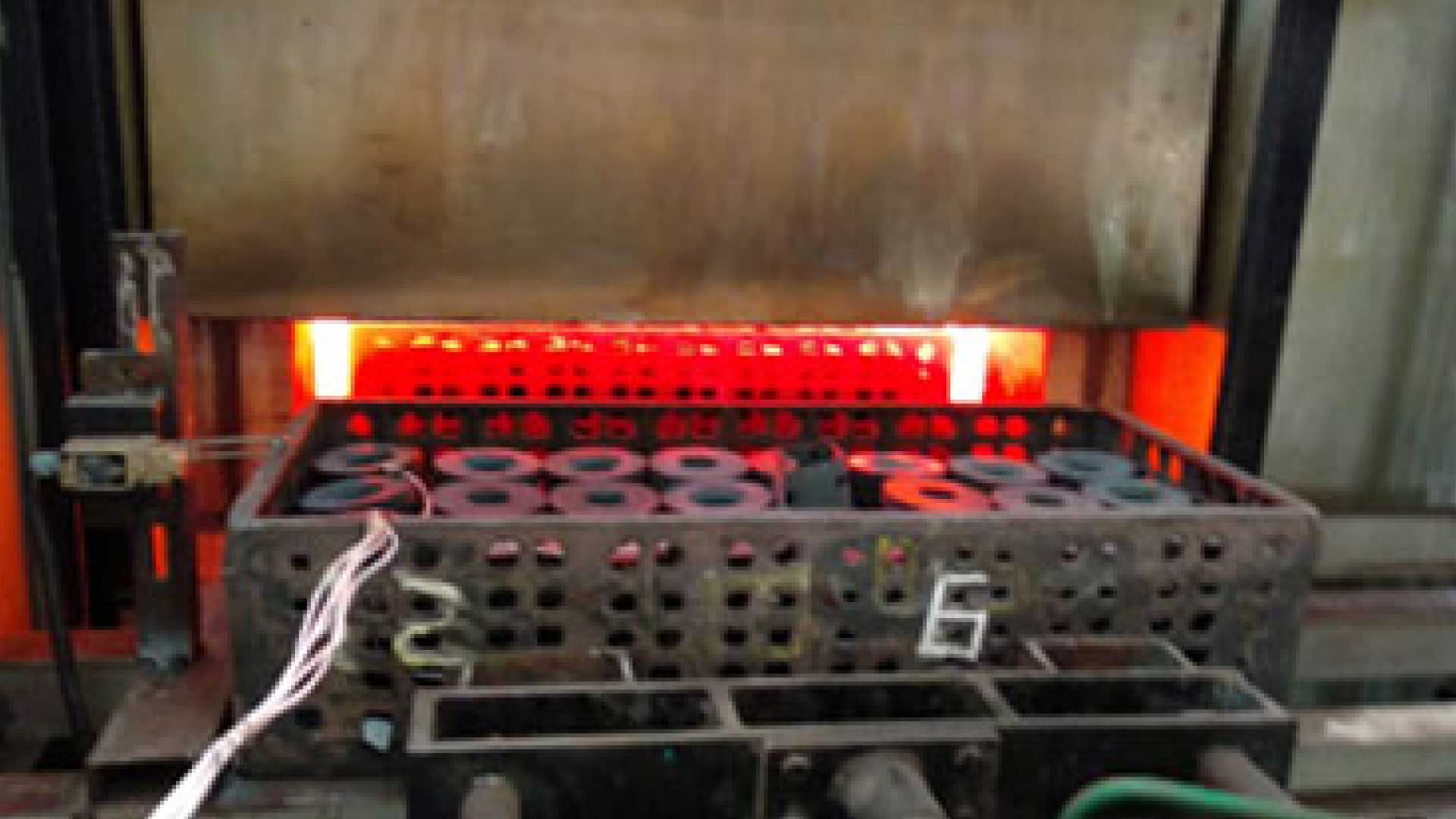

Muffele Furnace

- Home

- Muffele Furnace

Muffele Furnace Calibration in Bangladesh

Muffele furnaces are essential for laboratory and industrial applications, including chemical analysis, material testing, and high-temperature experiments. To ensure accurate results and prolong the lifespan of your equipment, Muffele Furnace Calibration is a crucial process. In Bangladesh, industries and laboratories are increasingly relying on precise calibration services to maintain quality and safety standards.

Importance of Muffele Furnace Calibration

Calibration of a muffele furnace ensures that the temperature readings are accurate and consistent. Over time, furnaces can drift from their set temperatures due to wear and tear, sensor inaccuracies, or environmental factors. Without regular calibration:

-

Test results may become unreliable.

-

Materials could be damaged due to overheating or underheating.

-

Compliance with industry standards may be compromised.

By calibrating your muffele furnace, you ensure operational efficiency, precise temperature control, and reliable testing outcomes.

Calibration Services in Bangladesh

In Bangladesh, specialized calibration service providers offer professional muffele furnace calibration. Services typically include:

-

Temperature Verification: Ensuring the furnace reaches and maintains the set temperatures accurately.

-

Sensor Testing: Checking thermocouples and controllers for accuracy and reliability.

-

Documentation: Providing calibration certificates that comply with industry standards.

Choosing an experienced and certified calibration service provider is crucial for maintaining the integrity of laboratory and industrial results.

Why Choose Pico Labs Ltd.

At Pico Labs Ltd., we specialize in providing top-notch calibration services for muffele furnaces across Bangladesh. Our certified technicians use advanced tools to ensure precise calibration, minimizing errors and improving efficiency. Whether it’s for industrial use or laboratory applications, we ensure your equipment delivers accurate performance every time.

Promotional Line: “Pico Labs Ltd. — Your trusted partner for reliable and precise muffele furnace calibration in Bangladesh.”

Benefits of Regular Calibration

Regular calibration of your muffele furnace provides several benefits:

-

Accuracy: Ensures test results are reliable and consistent.

-

Safety: Reduces the risk of equipment failure or hazards.

-

Compliance: Meets national and international standards.

-

Longevity: Extends the operational life of your furnace.

Investing in professional calibration services like those offered by Pico Labs Ltd. helps maintain the integrity of your operations while safeguarding your equipment and results.

In conclusion, proper Muffele Furnace Calibration in Bangladesh is indispensable for industries and laboratories aiming for precision, safety, and compliance. Partnering with a trusted provider like Pico Labs Ltd. ensures your furnace performs at its best, every time.