Temperature Controller Calibration in Bangladesh

Temperature controllers are critical devices in industrial and laboratory environments. Accurate temperature control ensures optimal performance, safety, and product quality. Over time, these controllers may drift from their set points due to environmental factors, wear and tear, or operational conditions. This makes temperature controller calibration essential to maintain accuracy and reliability.

What is Temperature Controller Calibration?

Temperature controller calibration is the process of verifying and adjusting the controller’s performance against a known standard. It ensures that the controller provides accurate readings and maintains the desired temperature within a specified tolerance. Calibration helps prevent costly errors, equipment damage, and process inefficiencies.

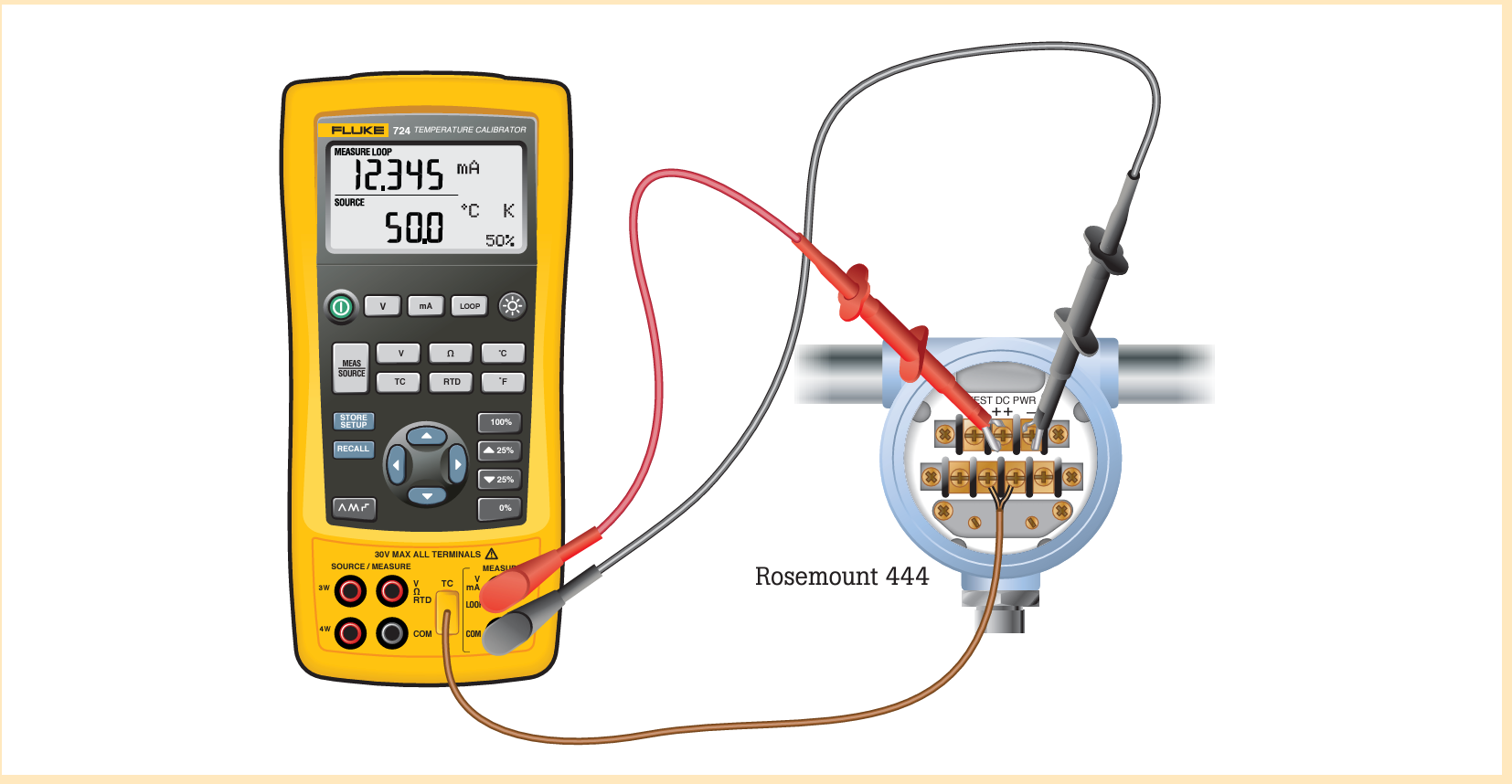

During calibration, a certified technician compares the controller’s output with a reference thermometer or temperature standard. Any deviation is corrected to bring the device back to precise performance. Regular calibration schedules depend on usage, environmental conditions, and the critical nature of the processes involved.

Importance of Temperature Controller Calibration

-

Accuracy and Reliability: Regular calibration ensures controllers deliver precise temperature control, which is vital for industrial processes like chemical manufacturing, food processing, and pharmaceuticals.

-

Quality Assurance: Maintaining accurate temperatures is critical for consistent product quality and compliance with industry standards.

-

Energy Efficiency: Properly calibrated controllers optimize energy use by preventing overheating or overcooling.

-

Safety: Prevents accidents caused by incorrect temperature regulation, protecting both personnel and equipment.

Temperature Controller Calibration Services in Bangladesh

In Bangladesh, industries and laboratories increasingly recognize the importance of professional calibration services. Pico Labs Ltd. offers expert temperature controller calibration services tailored to meet both industrial and laboratory standards. Our experienced technicians use advanced calibration equipment to ensure your controllers perform with maximum accuracy.

We provide:

-

Calibration for all types of temperature controllers, including digital, analog, and programmable units.

-

On-site and in-house calibration services for convenience and minimal downtime.

-

Detailed calibration certificates that comply with international standards.

Why Choose Pico Labs Ltd.?

At Pico Labs Ltd., we combine technical expertise with modern calibration technology to deliver reliable results. Our team prioritizes accuracy, efficiency, and customer satisfaction. By choosing us, you ensure your temperature controllers are calibrated to the highest standard, reducing operational risks and improving process performance.

Promotional Line: “Trust Pico Labs Ltd. – Bangladesh’s leading experts in temperature controller calibration, delivering precision, reliability, and excellence for your business.”

Regular temperature controller calibration is not just a maintenance task—it is an investment in safety, quality, and efficiency. Industries in Bangladesh can rely on professional services from Pico Labs Ltd. to maintain peak performance and compliance with international standards.