- We

- Renewable Energy

- Calibration Service

-

Testing & Inspection

- Annual Inspection

- Energy Audit

- Transformer Testing

- Condition Monitoring

- HiPot Testing

- Circuit Breaker Test

- Insulation Testing

- CT/PT Analysis

- Earthing Inspection

- Environmental Inspection

- Flue Gas Analysis

- LV, MV, HV Switchgear Testing

- DEA (Detail Engineering Assessment)

- Correlation of Compressive Strength of Concrete

- Mapping Homogeneity of Concrete Test

- Defects of Concrete Subsurface Test

- Concrete Pile Length Assessment Test

- Mapping of Concrete Plate Thickness

- Pile’s Internal Defects, Voids Assessment Test

- Pile Load Test

- Concrete Column Test

- Pipes Hardness Test

- Heat-Treated Surfaces Inspection

- Rebar location Assessment

- Crack Assessment

- Metal Detection & Analysis

- Drilling Spot Findings

- Concrete Compressive Strength

- Concrete Uniformity Mapping

- Shallow Utility Location Assessment

- Pipeline Inspection & Assessment

- Excavation Safety Assessment

- Utility Locating & Mapping

- Penetration Test

- Welding Inspection of Pressure Vessel

- Defects Analysis in Welding

- Adhesive Strength Test

- Pull Off Testing

- Skid Resistance Test of Construction Floors

- Concrete Resistance Measurement

- Building Information Modeling (BIM)

- Augmented Reality (AR) Assessment

- Virtual Reality (VR) Assessment

- Digital Twin Creation

- Partial Discharge Analysis

- Power Quality Analysis

- Photovoltaic Test

- Relay Testing

- SF6 Leak Detection

- Surge Protection Device

- Shaft Alignment Diagnosing

- Substation Testing & Commissioning

- Thermography Analysis

- Ultrasonic Flow Analysis

- Ultrasound Leak Detection

- Conveyer Belt Inspection

- Videoscope Inspection

- Switchgear Testing Service

- Solar Irradiance Measurement Service

- Contact Resistance Test Service

- Rent Products

Hot Air Oven

- Home

- Hot Air Oven

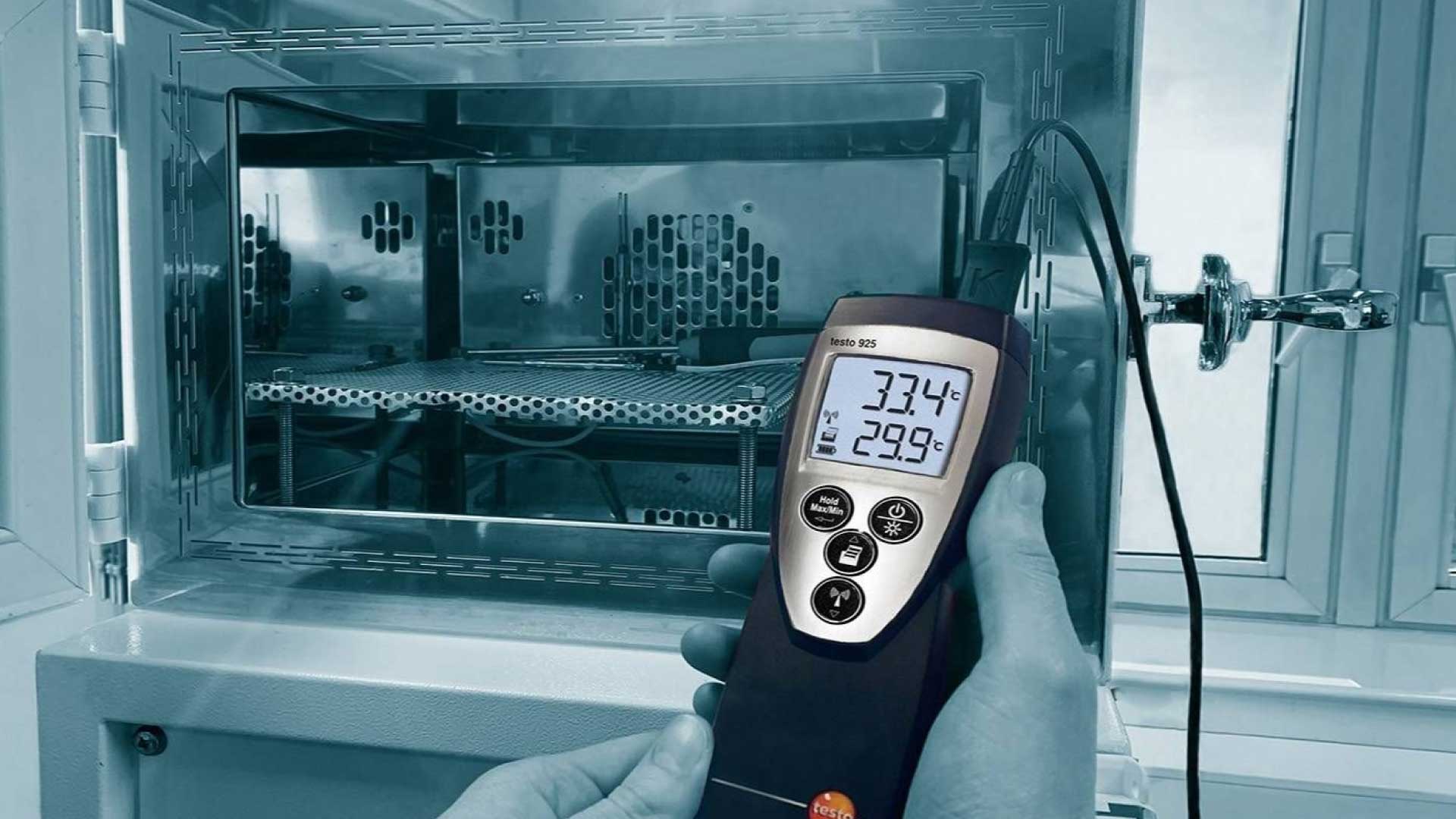

Hot Air Oven Calibration in Bangladesh

Hot air ovens are essential laboratory instruments used for sterilization, drying, and other critical processes in industries such as pharmaceuticals, food, and research laboratories. Ensuring that these ovens operate accurately is vital, as even minor deviations in temperature can compromise product quality and safety. This is where Hot Air Oven Calibration becomes crucial.

What is Hot Air Oven Calibration?

Hot air oven calibration is the process of verifying and adjusting the oven's temperature to ensure it operates within the specified accuracy range. During calibration, experts measure the oven’s performance using precise temperature sensors and compare it with standard reference points. Any discrepancies are corrected to maintain the accuracy and reliability of the equipment.

Importance of Hot Air Oven Calibration

-

Accurate Results: Proper calibration guarantees that laboratory experiments and industrial processes are conducted at the right temperature, ensuring consistent and reliable results.

-

Compliance: Many industries must adhere to national and international quality standards. Regular calibration helps meet these regulatory requirements.

-

Safety: Overheated or underheated ovens can pose safety hazards. Calibrated ovens reduce the risk of accidents and equipment damage.

-

Longevity: Routine calibration and maintenance prolong the life of the hot air oven, saving businesses from unnecessary replacement costs.

How is Calibration Done?

Calibration involves placing a high-precision thermometer or temperature logger inside the oven at multiple points. The oven is then set to a specific temperature, and the readings are compared against the reference. Any deviation is adjusted according to standard procedures. After calibration, a certificate is issued confirming the oven’s accuracy, which is essential for audits and quality control.

Why Choose Pico Labs Ltd. for Hot Air Oven Calibration in Bangladesh?

At Pico Labs Ltd., we specialize in calibration services for laboratory and industrial equipment. Our team of certified experts ensures that your hot air ovens are calibrated according to international standards, providing accurate and reliable results. We use state-of-the-art instruments and follow rigorous procedures to guarantee precision.

Our clients across Bangladesh trust us for:

-

Timely and professional calibration services

-

Detailed calibration reports and certificates

-

Cost-effective and reliable solutions

-

On-site calibration for convenience

Regular calibration of your hot air ovens not only ensures compliance and safety but also boosts confidence in your processes and results. By partnering with Pico Labs Ltd., you ensure your equipment operates at peak performance, supporting quality assurance and operational excellence.

Hot air oven calibration is a vital process for any laboratory or industrial setting. With Pico Labs Ltd., you get reliable, accurate, and professional calibration services across Bangladesh. Ensure the longevity, safety, and accuracy of your hot air ovens today by choosing a trusted calibration partner.