- We

- Renewable Energy

- Calibration Service

-

Testing & Inspection

- Annual Inspection

- Energy Audit

- Transformer Testing

- Condition Monitoring

- HiPot Testing

- Circuit Breaker Test

- Insulation Testing

- CT/PT Analysis

- Earthing Inspection

- Environmental Inspection

- Flue Gas Analysis

- LV, MV, HV Switchgear Testing

- DEA (Detail Engineering Assessment)

- Correlation of Compressive Strength of Concrete

- Mapping Homogeneity of Concrete Test

- Defects of Concrete Subsurface Test

- Concrete Pile Length Assessment Test

- Mapping of Concrete Plate Thickness

- Pile’s Internal Defects, Voids Assessment Test

- Pile Load Test

- Concrete Column Test

- Pipes Hardness Test

- Heat-Treated Surfaces Inspection

- Rebar location Assessment

- Crack Assessment

- Metal Detection & Analysis

- Drilling Spot Findings

- Concrete Compressive Strength

- Concrete Uniformity Mapping

- Shallow Utility Location Assessment

- Pipeline Inspection & Assessment

- Excavation Safety Assessment

- Utility Locating & Mapping

- Penetration Test

- Welding Inspection of Pressure Vessel

- Defects Analysis in Welding

- Adhesive Strength Test

- Pull Off Testing

- Skid Resistance Test of Construction Floors

- Concrete Resistance Measurement

- Building Information Modeling (BIM)

- Augmented Reality (AR) Assessment

- Virtual Reality (VR) Assessment

- Digital Twin Creation

- Partial Discharge Analysis

- Power Quality Analysis

- Photovoltaic Test

- Relay Testing

- SF6 Leak Detection

- Surge Protection Device

- Shaft Alignment Diagnosing

- Substation Testing & Commissioning

- Thermography Analysis

- Ultrasonic Flow Analysis

- Ultrasound Leak Detection

- Conveyer Belt Inspection

- Videoscope Inspection

- Rent Products

Temperature IR Gun

- Home

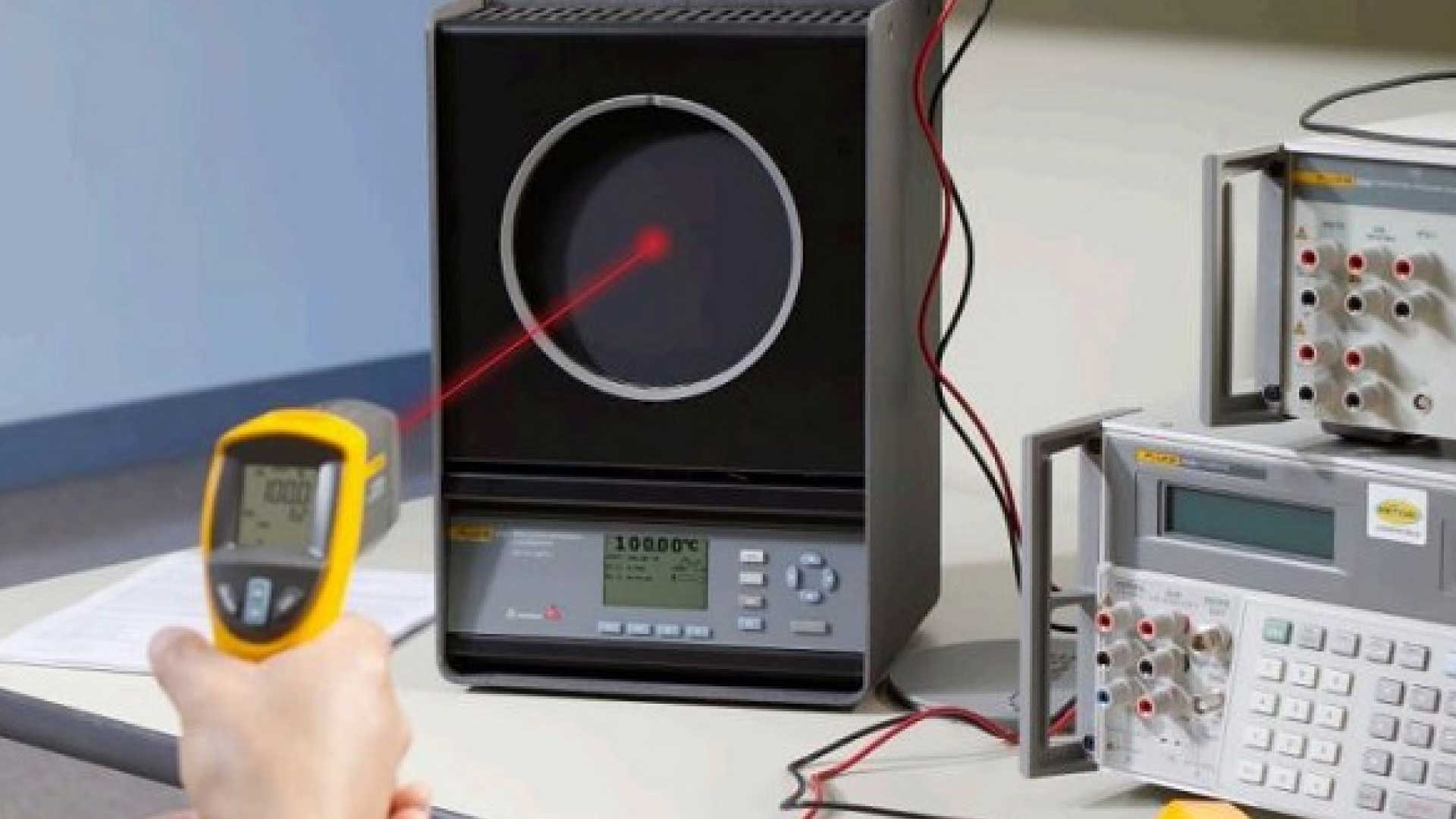

- Temperature IR Gun

Temperature IR Gun Calibration in Bangladesh

Temperature IR guns are essential tools for accurate, non-contact temperature measurement in industries such as food processing, pharmaceuticals, manufacturing, and HVAC systems. Ensuring that these devices provide precise readings is critical for safety, quality control, and operational efficiency. This is where Temperature IR Gun Calibration plays a vital role.

At Pico Labs Ltd., we specialize in professional Temperature IR Gun Calibration in Bangladesh, helping businesses maintain the accuracy of their instruments and comply with industry standards.

Why Temperature IR Gun Calibration is Important

Over time, IR guns can drift due to environmental factors, usage, or sensor degradation. If an IR gun provides inaccurate readings, it can lead to:

-

Compromised safety: Incorrect temperature readings can affect food safety or industrial processes.

-

Quality issues: Manufacturing processes may produce substandard products.

-

Operational inefficiency: Machines and processes may not perform optimally.

Calibration ensures that your IR gun readings match a certified reference, guaranteeing precise measurements every time. Regular calibration is not just a recommendation; it is a necessity for businesses that prioritize accuracy and compliance.

How Pico Labs Ltd. Provides Calibration Services

At Pico Labs Ltd., we offer:

-

Certified Calibration: Our calibration process adheres to international standards, ensuring your IR gun meets the highest accuracy requirements.

-

Fast Turnaround: We understand the importance of your operations, so we provide timely calibration without compromising quality.

-

Detailed Calibration Report: Every service comes with a comprehensive report detailing the results, traceability, and adjustments made.

-

Expert Team: Our experienced technicians handle all types of IR guns with precision and care.

By choosing Pico Labs Ltd., you ensure your Temperature IR Gun operates with optimal accuracy, helping you maintain safety, efficiency, and compliance across all operations.

Industries That Benefit

Businesses across various sectors in Bangladesh rely on IR gun calibration, including:

-

Food & Beverage Processing

-

Pharmaceuticals & Healthcare

-

Manufacturing & Production

-

HVAC & Electrical Services

Regular calibration reduces downtime, improves quality control, and enhances workplace safety.

Investing in proper calibration services today can prevent costly errors tomorrow. Contact Pico Labs Ltd. to schedule your Temperature IR Gun calibration and keep your operations running smoothly.