Airflow Meter Calibration in Bangladesh

Airflow meter calibration is one of the most essential processes in ensuring accurate measurement and control in various industries. In Bangladesh, where industrial development is rapidly growing, precision in airflow measurement plays a crucial role in maintaining efficiency, safety, and environmental standards. From HVAC systems to manufacturing plants, accurate airflow monitoring directly impacts energy usage and product quality.

What is Airflow Meter Calibration?

Airflow meter calibration is the process of verifying and adjusting the accuracy of airflow measuring devices. Over time, due to wear, dust, temperature, and environmental factors, airflow meters can lose accuracy. Calibration ensures the device readings remain within a defined range of accuracy when compared with a known standard.

During calibration, the airflow meter is tested against a reference device under controlled conditions. Any deviation is recorded and corrected to ensure the meter provides precise readings in real-world applications.

Importance of Airflow Meter Calibration in Industries

In Bangladesh, industries such as power plants, pharmaceuticals, HVAC, textiles, food processing, and environmental testing heavily rely on airflow meters. Proper calibration helps in:

-

Accurate Measurement: Ensures the flow readings reflect true air volume or velocity.

-

Energy Efficiency: Optimizes system performance, reducing unnecessary energy loss.

-

Compliance with Standards: Meets ISO, BS, and other international calibration standards.

-

Safety Assurance: Prevents system malfunctions that could lead to hazards.

-

Cost Savings: Avoids equipment damage and production downtime due to incorrect readings.

When Should You Calibrate Your Airflow Meter?

Most experts recommend calibrating an airflow meter at least once every 12 months. However, in environments where the device is exposed to extreme conditions or used continuously, calibration should be more frequent. Indicators that your airflow meter may need calibration include inconsistent readings, performance drift, or sensor errors.

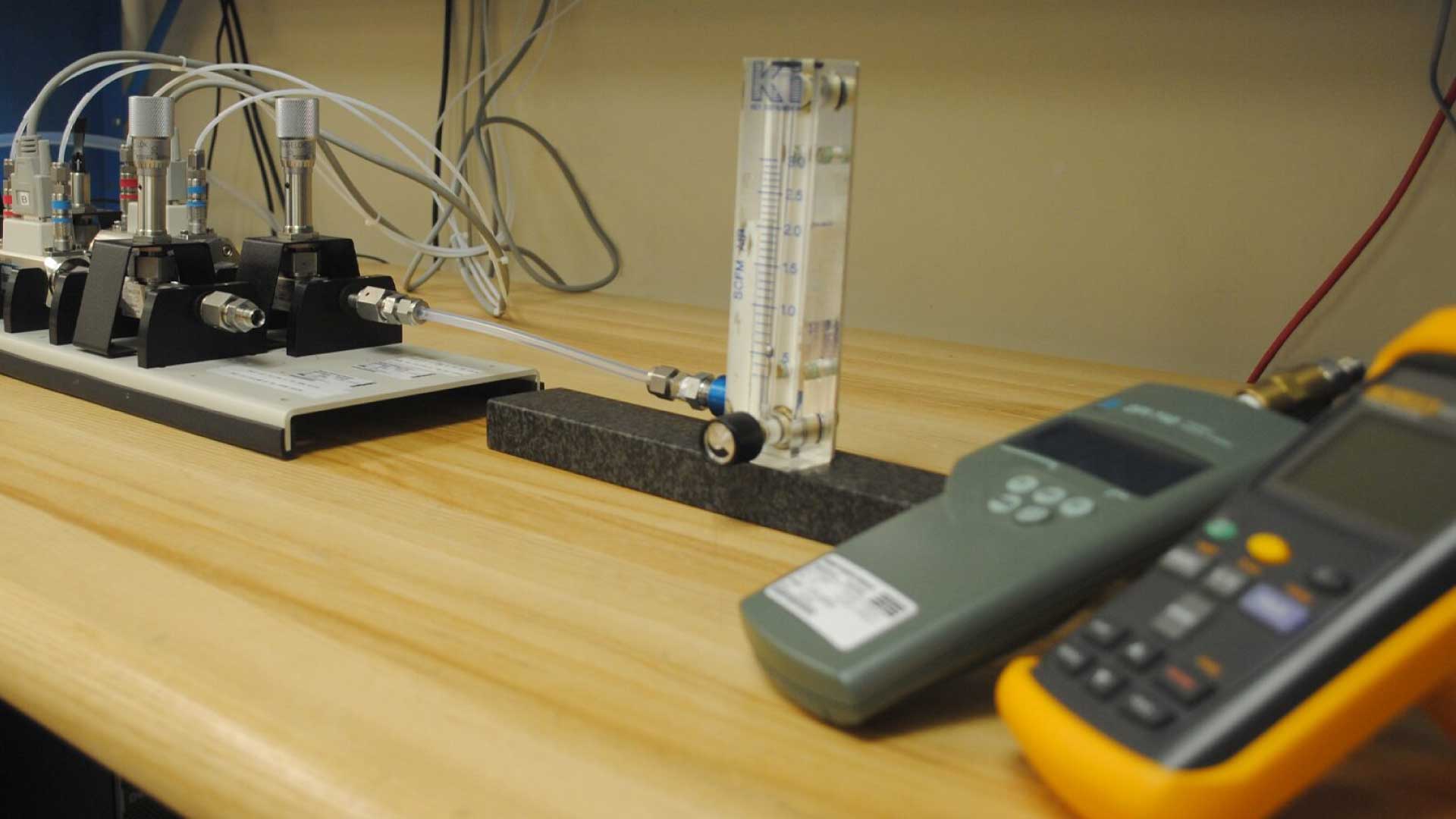

Airflow Meter Calibration Process

The calibration process involves several key steps to ensure accuracy:

-

Inspection: The device is visually checked for damage or contamination.

-

Setup: The airflow meter is connected to a calibration bench or wind tunnel.

-

Testing: The meter’s output is compared to a reference standard at multiple flow points.

-

Adjustment: Deviations are corrected through fine-tuning or software calibration.

-

Verification: Final readings are checked to confirm the meter meets accuracy standards.

-

Certification: A calibration certificate is issued, documenting all results and traceability.

Airflow Meter Calibration Standards in Bangladesh

Leading calibration service providers in Bangladesh follow international and national standards such as:

-

ISO/IEC 17025 Calibration Laboratory Accreditation

-

ASTM Standards for Airflow Measurement

-

BS EN Standards for Flow Testing

These standards ensure that calibration services are reliable, traceable, and recognized globally.

Why Choose Professional Calibration Services?

While some companies attempt in-house calibration, professional calibration services offer advanced tools, certified reference instruments, and expert technicians. This ensures that your airflow meters perform optimally with traceable accuracy.

Pico Labs Ltd. – Trusted Airflow Meter Calibration Service in Bangladesh

Pico Labs Ltd. is a leading name in Power & Energy Calibration Services in Bangladesh, offering precise and reliable Airflow Meter Calibration for various industrial sectors. Our state-of-the-art laboratory is equipped with advanced instruments and experienced engineers who ensure every calibration meets international standards.

We provide:

-

Calibration of all major airflow meter brands.

-

Fast turnaround time with detailed calibration reports.

-

On-site and laboratory calibration services.

-

Affordable service packages tailored to client needs.

Airflow meter calibration is not just a technical requirement—it’s an investment in accuracy, safety, and efficiency. With Bangladesh’s growing industrial demand, ensuring your airflow meters are calibrated by experts like Pico Labs Ltd. will help you maintain compliance, improve system performance, and build trust in your operations.